PRODUCTS

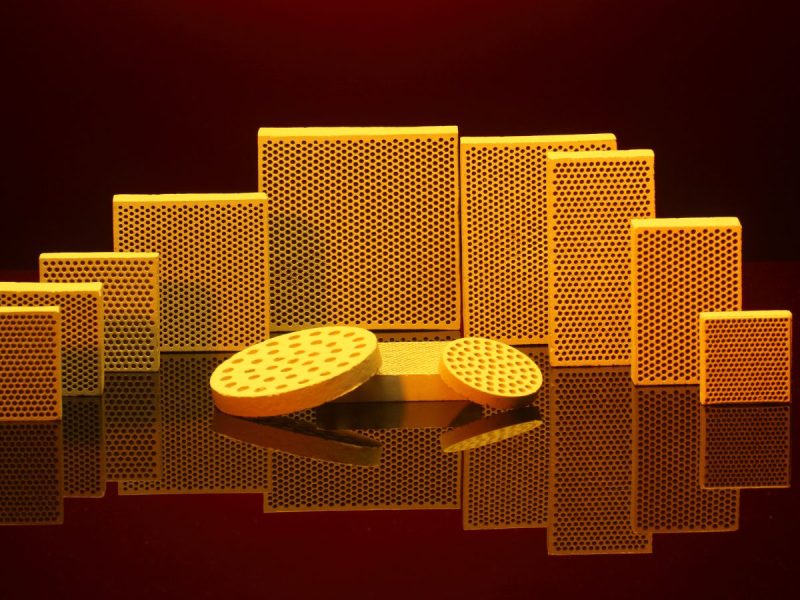

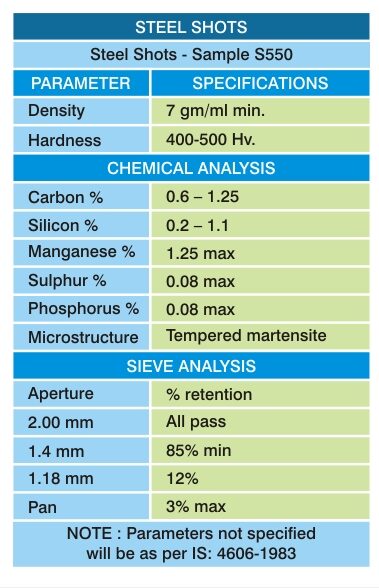

Ceramic Press Filters

The foundry industry suffers high rejection rates resulting on account of inclusions in metal cast, which amount to huge losses and wastage. Such inclusions are easily trapped with the help of our Press Filters. Our world class range of precision pressed Ceramic round-hole filters are produced with indigenous technology and special tools. This ensure homogeneity at the application stage and offers high levels of dimensional stability for large casting weighing upto 60T. Florence International’s Press Filters enjoy great demand amongst leading players in Grey Iron casting, SG Iron Casting, Steel Casting, Heavy & light Metal alloy Casting industry. Florence filters can be used in Horizontal, Vertical and Inclined position

Our Ceramic Filter mainly use in following Automobile Castings

Advantages of Ceramic Filter :

- Cost effective product

- Dimensionally accurate

- Encourage laminar flow / consistent flow rate

- Deformation resistant and stable throughout entire poring

- Uniform pore size

- Minimize non-metallic inclusions

- Can be placed below down sprue

- Indigenous manufacturing facility with eco friendly process

Ferro Alloys

Ferro Silicon

Ferro Silicon is a ferro alloy that is made with the addition of high percentage of silicon content. This alloy is used as a source of silicon and also find applications of reducing oxides from metals.

![]()

Silico Manganese

Silico Manganese is an alloy containing the high amount of manganese and silicon. It finds extensive applications as deoxidizer and an alloying element in steel and also in casting manufacturing. It is used as an additive in molten metal.

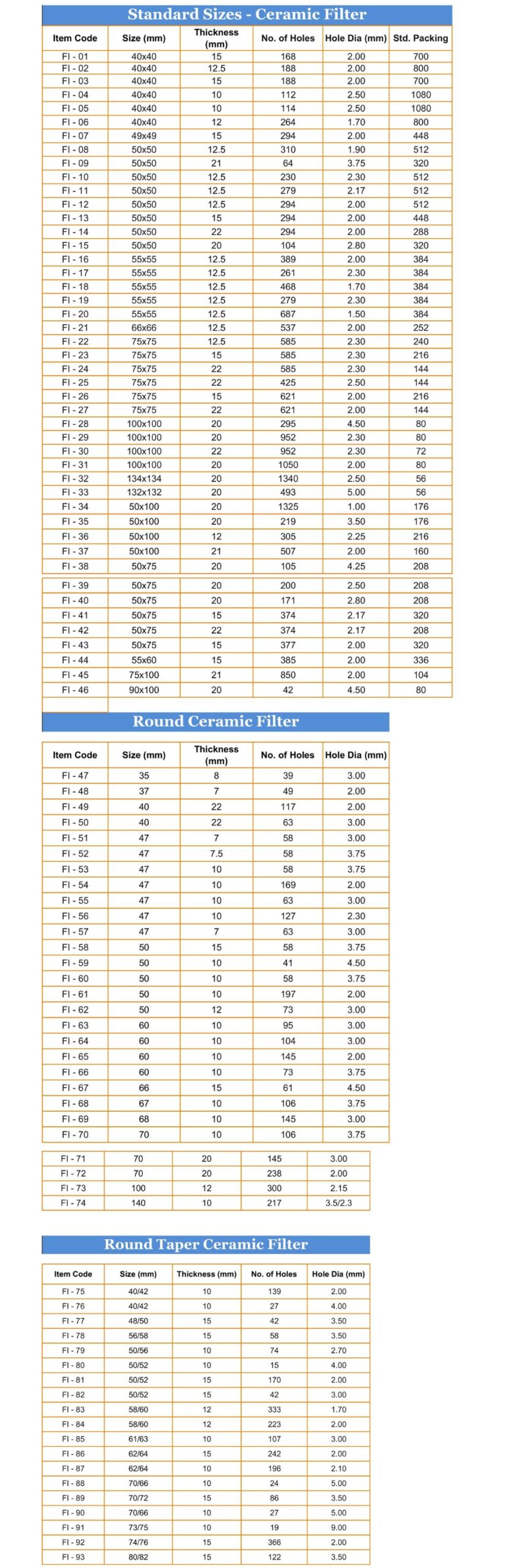

Ferro Chromium

Ferro chrome (Fe Cr) is an alloy of chromium and iron containing between 60% and 64% chromium. Ferro Chromium increases tensile strength, hardness, toughness and also the casting ability to withstand elevated temperature.

Silicon Carbide

Silicon Carbide is an Silicon and Carbon alloying additive, used in induction and cupola furnaces for cast iron and SG iron production. Silicon Carbide allows to provide the necessary alloying elements while reducing the quantities of additives needed and the energy consumption compared to substitute materials such as ferro-silicon, therefore improving the overall economics of iron and steel production.

![]()

Iron Sulphide

Iron sulphide is a blend of Iron and Sulphur, which is used to maintain the chemical composition of Iron and sulphur in molten metal.

Refractory Products

High Alumina Bricks

Florence manufactures a wide range of Fire Clay and High Alumina bricks for foundries and steel melting industry. Our bricks are manufactured to meet highest international quality standards and designed to offer high heat resistant properties and durability. To match the diverse needs of our clients, we manufacture the bricks available in various grades and specifications.

Castables

Castables are widely used for cementing and adhesive purposes in foundry and steel industries. Florence International offers a range of high quality dense and low cement castables to meet every need and for use in high temperature applications. Our high quality castables are acclaimed for their excellent quality, long shelf life, accurate composition, effectiveness and high flexibility to mold in any shape. Castables are available in various grades to suit client's requirement.

Calcined Petroleum Coke

Calcined Petroleum Coke

Florence provides one of the highest grade of CPC for industrial use. Calcined Petroleum Coke (CPC) is a form of highly electrically conductive, dense Carbon with very low specific Electrical Resistance and having fixed carbon of approximately 99.5%. Sulphur content is < 1%.

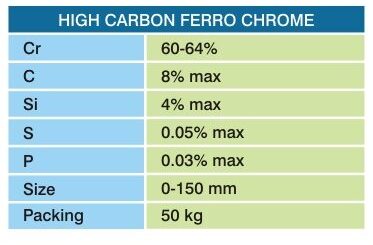

Steel Shots

Steel shots

Steel shots are used in the fettling department for cleaning of casting by shot blasting process.

Copper

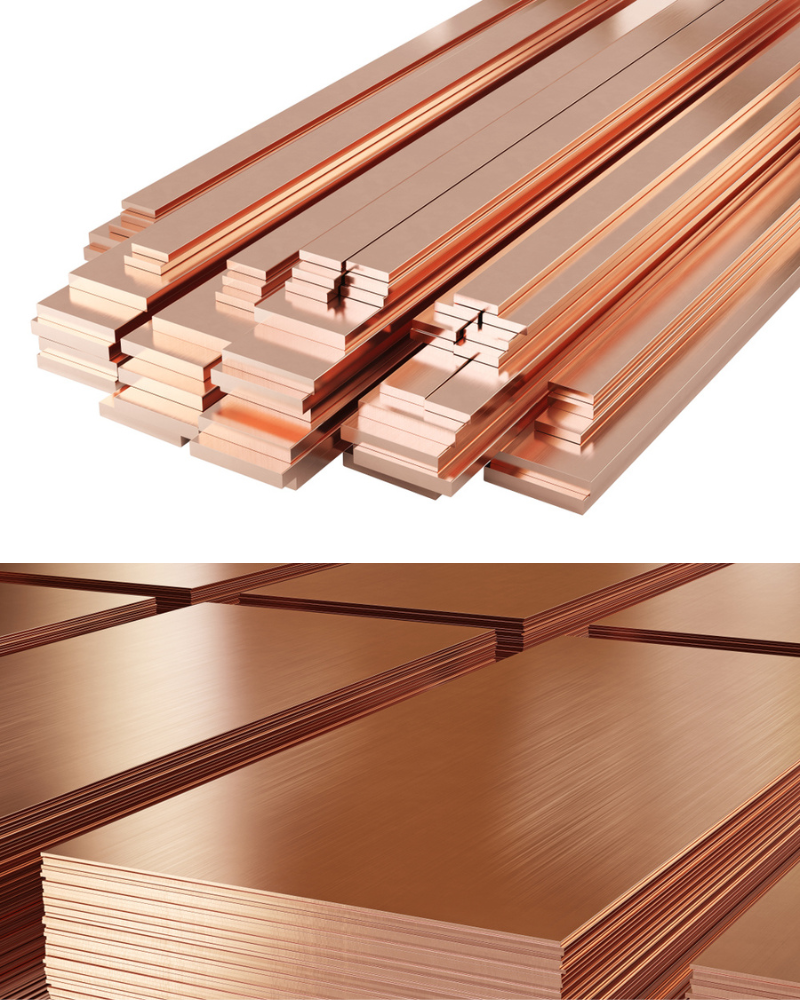

Copper

Copper is far more than a decorative metal, though. Copper, with its reddish-brown color, is an easily recognizable non-ferrous metal. Being non-ferrous makes copper non-magnetic. Copper's properties make it ideal for industrial applications, including metal stamping. Copper has a variety of desirable mechanical and chemical properties, making it one of the most versatile and extensively used materials. Copper’s properties can be further enhanced through the use of metal alloys making it the ideal choice for a wide range of metal stamping applications.

Copper Bars are demanded for their superior conductivity and for properties like crack resistance and free bend-ability. Here, we also ensure that the end solutions offered assist in improving the thermal characteristics of copper flat bars. Some of the benefits provided by these bars include superior conductivity for better carrying capacity, superior dimensional control, crack - free bends, lower inductance, lower impedance, improved thermal characteristics and others.

Available Range : Copper Bus Bars, Copper Flat Bars, Copper Square Bars, Copper Round Bars, Copper Hex Bars, Copper Braided Bus bar and Copper Laminated Bus bar.

Our product range includes a wide range of bare copper conductor, red copper foil, copper ingots, copper sheet, copper tinned & bare wire and electrolytic copper.